- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Product Description

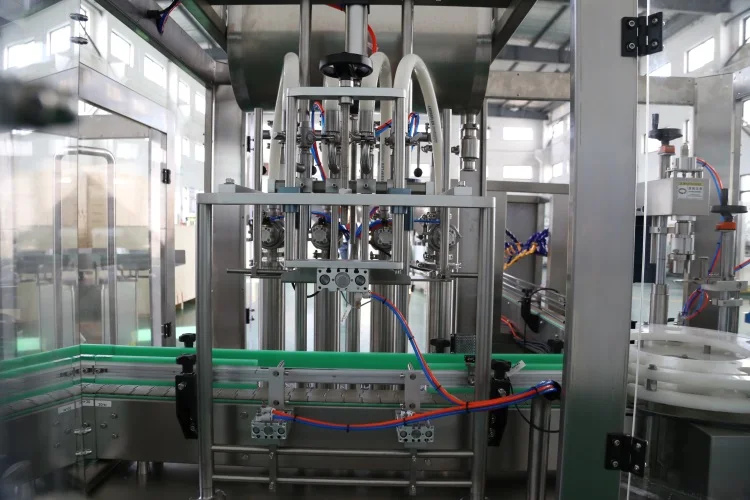

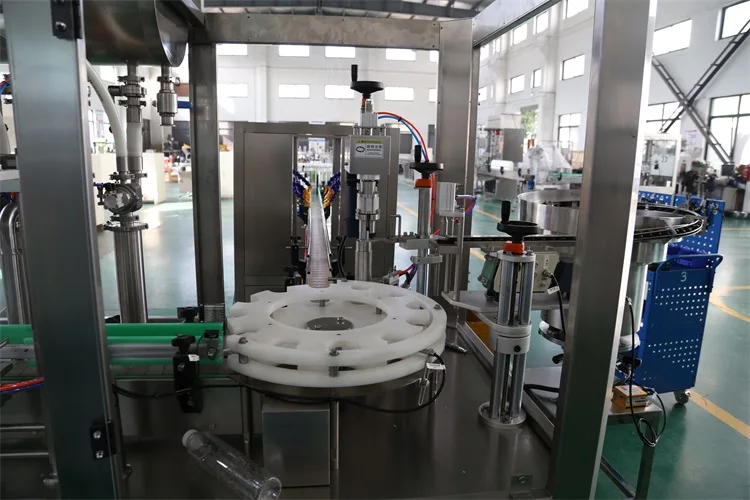

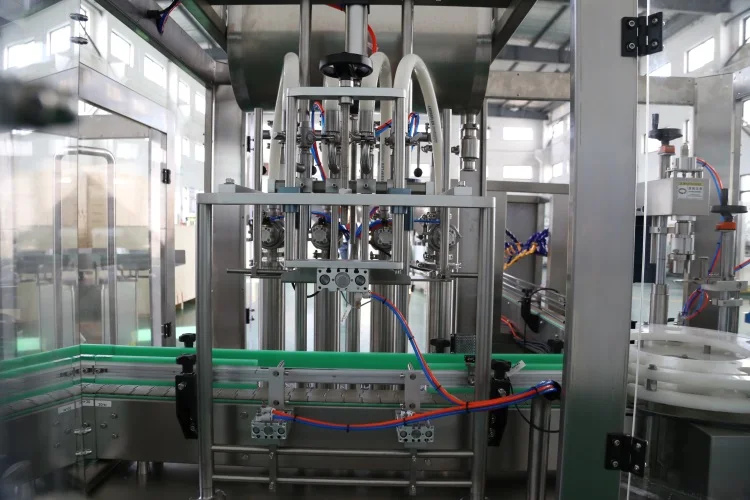

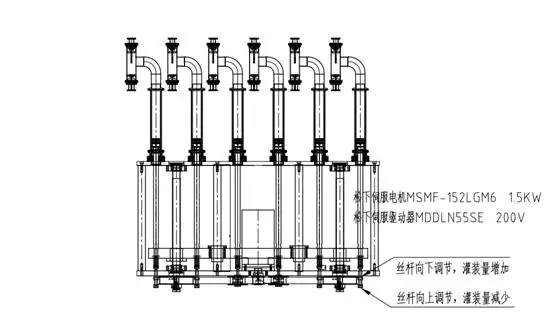

| Product | Drink Juice Water Liquid Filling Line |

| Output | 1500-6000BPH |

| Filling Volume | 10-5000ML |

| Control | PLC and Touch Screen |

| Bottle Size | Customized |

| Capping Type | Screwing, Pressing, Crimping and so on |

| Bottle Type | Glass, Plastic, Metal |

| Driving Motor | Servo Motor |

| Power | 1.8KW |

| Voltage | 220/380V, 50/60Hz |

| Machine Frame Material | SS304 |

| Capping Motor | Magnetic Torque Motor |

| FEATURES | BENEFITS |

| Flexible label head tilts on x-y axis | Great for round, tapered or shaped containers |

| Manual Adjustments | |

| Adjustable applicator height | Suitable for a wide variety of containers and labels |

| Adjustable conveyor height | Easy to adapt to any existing packaging line |

| Manual position setting | Easy to use adjustments ensure labels are placed accurately on the container |

| Touch Screen Controls | |

| 5.5” color LCD touch screen controls | Easier operation of controls |

| Touch screen rotates 360 degrees | Allows the machine to be controlled from any position |

| Stores up to 30 product settings | Faster and more accurate setup |

| Built-in operating instructions | Enables quick setup and easy changeover |

| Easy to follow fault instructions | Enables operator to quickly identify and fix problems |

| Screensaver | Reduces the risk of screen burn |

| Data storage for maintenance and usage | Simplifies scheduling of maintenance activities |

| Built-in printer controls | Allows for ‘plug & play’ future printer upgrades |

| FEATURES | BENEFITS |

| Sensor Features | |

| Production pre-set - stop function | Automatically stops once the pre-set quantity has been met |

| Missing label auto stop system | Ensures all products are labeled |

| Label countdown | Allows operator to monitor run progress |

| Batch counter | Easy to keep track of batches |

| Label counter | Simplifies regulatory tracking of labels |

| Container/production run counter | Provides total production quantity |

| Label position set | Ensures labels are placed correctly on product |

| One touch label sensor | Allows operator to use “one touch” feature on sensor to “teach” the sensor the label characteristics |

| Auto label sensor set | Detects labels and setup machine automatically from touch screen |

| Auto label length set | Detect label lengths and setsup machine automatically from touch screen |

| Design and Construction | |

| Adjustable to 8 speeds | Easily adjusts to line speeds |

| Battery free microprocessor | Maintains default settings and memory even after sitting idle for long periods |

| Slide-out controls and electronics stored in lower cabinet | Enables quick and easy servicing |

| Manufactured with stainless steel and anodized aluminum | Robust, long lasting construction with quick and easy cleanup |

| Manufactured to strict ISO 9001 standards | High quality, consistent manufacturing ensures easy repairs and/or upgrades |

| GMP compliant | Designed to easily surpass standards of compliance auditors |

| Fully synchronized controls | Ensures all components run at the proper speed |

| Stepper driven motor | Fine adjustment allows precise label placement |