- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

PAIXIE

| Availability: | |

|---|---|

| Quantity: | |

Product Description

Products Description

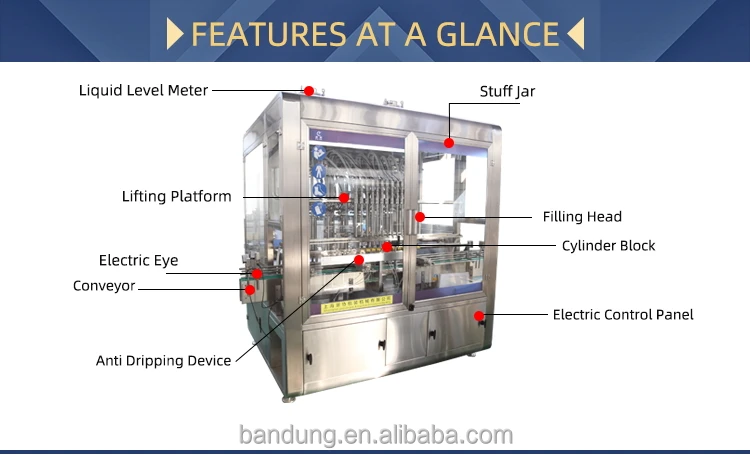

5. Using drip tight filling head,no leaking.

Application

Technical Parameters

| PX32-8 | PX18-6 | PX24-8 | PX32-8 |

| Capacity | 4000-6500BPH | 6500-8500BPH | 8500-11000BPH |

| Bottle Volume | 250ml-1L | 250ml-1L | 250ml-1L |

| Bottle diameater | 50-120mm(Customizable) | ||

| Bottle high | 150-320mm(Customizable) | ||

| Machine power | 1.5KW | 2.2KW | 3.7KW |

| Bottle Type | PET / PE / PP / Glass / Metal | ||

| Bottle Shape | Round / Square / Unique Shape | ||

| Suitable for filling products | Ketchup, honey, chili sauce, water, juice, cooking oil, liquid, shampoo, motor oil, eye drops, laundry detergent, hand soap,detergent, face cream, etc. | ||

| Machine packing method | Stretch film + wooden box packing | ||

Details Images

1.This filling machine could be linear tor rotary type which is designed according to customers capacity and filling volume. It suits different size of plastic and glass bottles, and the height of the filling nozzles is adjustable. The filling nozzles are made of SS304 or 316, resist high temperature filling. drip-proof , via photoelectric detection to ensure no bottle no filling.

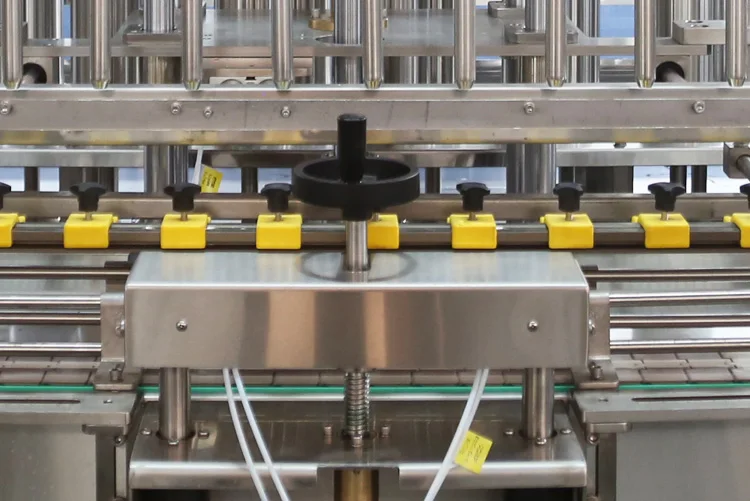

3.Handwheel For Easymachine Adjustment