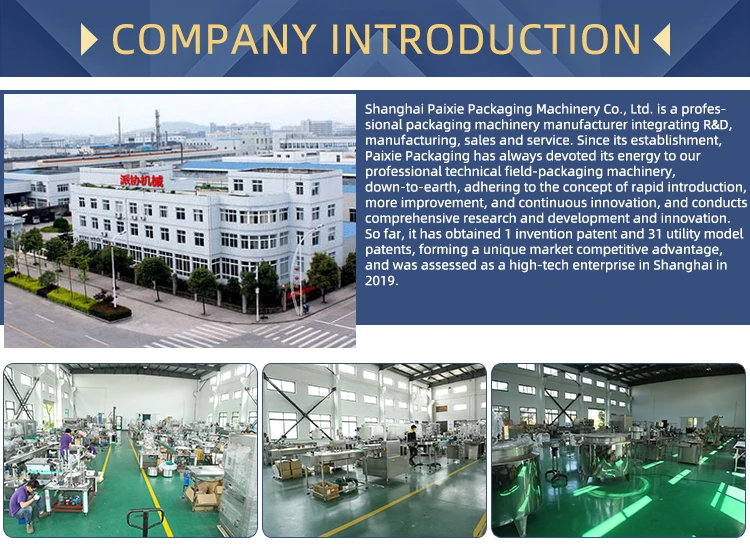

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

PX-BFC80

PAIXIE

| Availability: | |

|---|---|

| Quantity: | |

Product Description

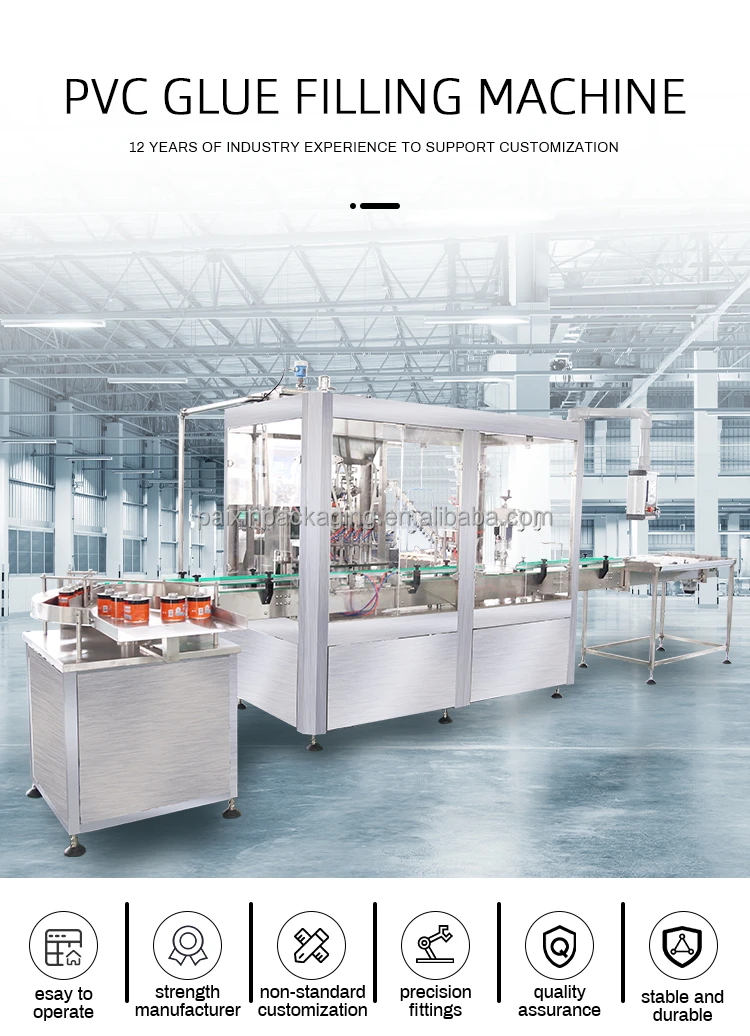

| Product | PVC glue automatic filling capping machine |

| Output | 1500-6000BPH |

| Filling Volume | 10-5000ML |

| Filling pump | ceramic pump |

| Control | PLC and Touch Screen |

| Bottle Size | Customized |

| Cap feeding | Elevator |

| Capping motor | Magnetic motor |

| Torquing range | 0-100N |

| Loading way | Motor pump loading |

| Capping Type | Screwing, Pressing, Crimping and so on |

| Bottle Type | Glass, Plastic, Metal |

| Driving Motor | Servo Motor |

| Power | 1.8KW |

| Voltage | 220/380V, 50/60Hz |

| Machine Frame Material | SS304 |

| Capping Motor | Magnetic Torque Motor |